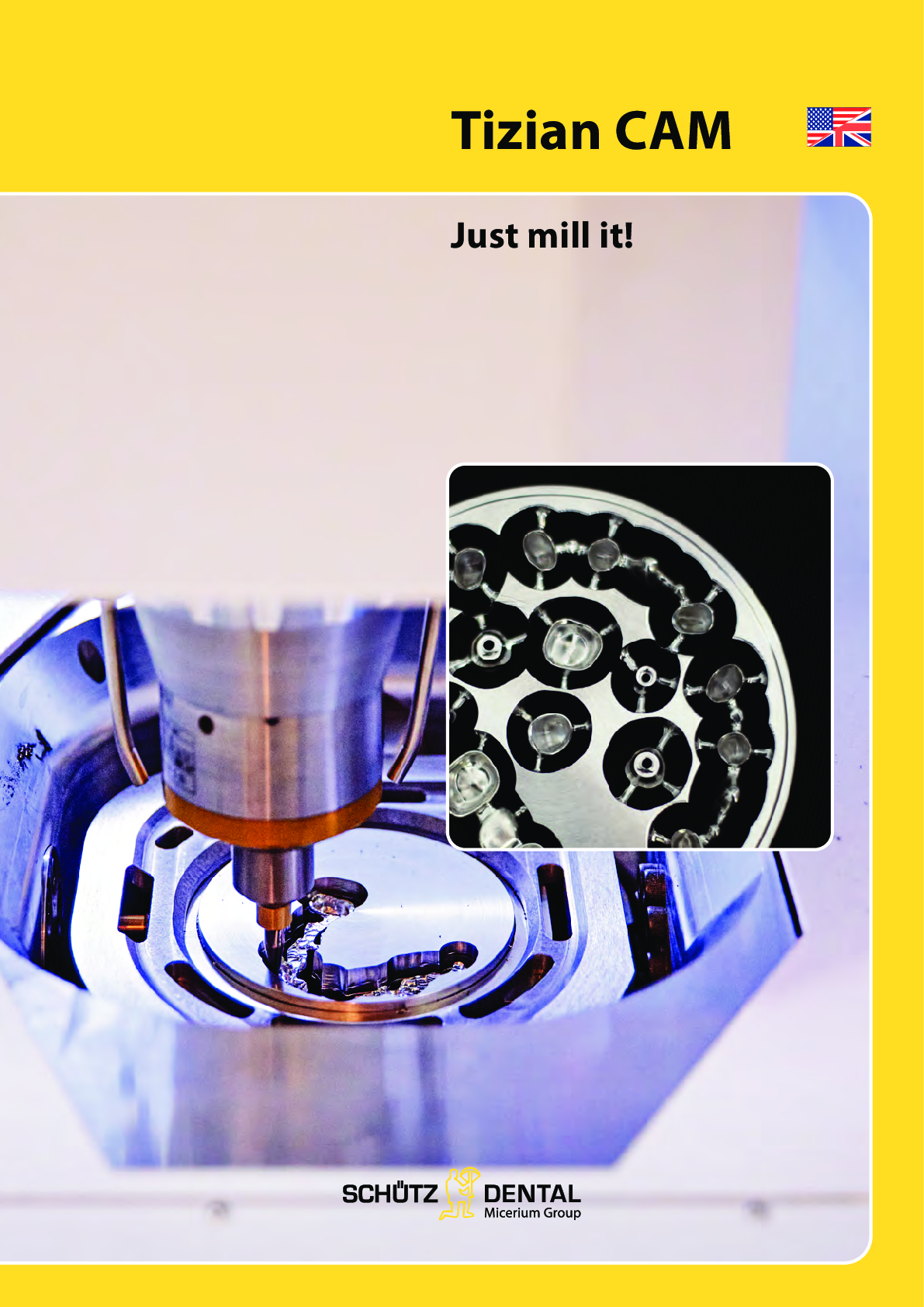

Tizian 3.5 Loader Pro, incl. 12x blank changer, 8 blank holder, wet processing & zero point clamping system

Advantages

- Blank storage for up to 12 blanks of different materials

- Revolutionary machine frame made from polymer concrete

- Simultaneous 5-axis processing

- Absolute measuring system in all axis

- Up to 20 % faster processing

Description

The ideal system for milled, adhesion-fixed secondary telescopic crowns and bridges.

The ideal system for milled, adhesion-fixed secondary telescopic crowns and bridges.

The milling systems Tizian 3.5 Pro and Tizian 3.5 Loader Pro were developed with an innovative machine concept which is adapted to today's demands on CAD/CAM production. Benefit from extraordinary stability and vibration-free processing due to the new one-part machine frame made from polymer concrete. Additionally, the high-definition, dynamic servo motors with an absolute measuring system facilitate a processing that is 20 % faster while still offering optimal precision.

Tizian 3.5 Pro - The automated all-in-one solution: Mill nearly all conventional dental CAD/CAM materials with only one milling machine. The outstanding precision of the machine even lets you process highly complex restorations such as one-part implant-supported constructions. Using the standard blank holder, the restorations are milled in five axes, with milling angles of up to 30 degrees. These advantages make the ""Tizian 3.5 Pro""-product line an excellent choice that will come up to the demands of modern dental labs and milling centers. The compact design makes the machines an alternative not only for large dental labs and milling centers, but also for small and medium-sized dental labs.

Tizian 3.5 Loader Pro - the pro solution: The integrated zero-point chuck system facilitates the use of a variety of adapter systems such as adapters for glass ceramic and different premilled systems. By using the novel open blank holder, you can mill restorations at angles of up to 90 degrees. What's more, the Tizian 3.5 Loader Pro with its fully automated blank storage lets you mill up to 12 different blanks in unmanned operation.

Your benefits:

- Blank storage for up to 12 blanks of different materials

- Revolutionary machine frame made from polymer concrete

- Simultaneous 5-axis processing

- Absolute measuring system in all axis

- Up to 20 % faster processing

- Wet or dry milling

- Processing all significant materials in dental industry, including metal processing

- Axial angle of up to +/- 30 degrees

- Milling of the front of the blank is possible (B-axis in 90 degree position)

- Jäger HF spindle with up to 60,000 rpm

Technical data:

Number of axis and type of processing: 5 axis simultaneously

Max. milling angle when processing a 98 mm blank: A-axis +/- 30 degrees, B-axis +/- 25 degrees

Max. axial angle A-axis: 360 degrees, B-axis: 115 degrees

Wet milling: integrated

Revolution max./Pmax~: 60,000 rpm/1 kW

Axial drive: AC servo motors with absolute encoder 0.15 µm

Tool receptacle: 6 mm shaft

Tool changer: 20-fold with protective cover against milling dust

Blank changer: fully automated, 8-fold (optional: up to 12-fold)

Weight: 250 kg

Width x depth x height: 1058 x 790 x 857 mm

Mains supply/frequency/performance: 100 V-240 V, 50/60 Hz, 2200 W

Compressed air supply: 6-9 bar constant flow, 60 liter/minute

Materials: CoCr/NEM, titanium, zirconium dioxide, aluminium oxide, PMMA, resins, composites, wax, glass ceramic, hybrid ceramic