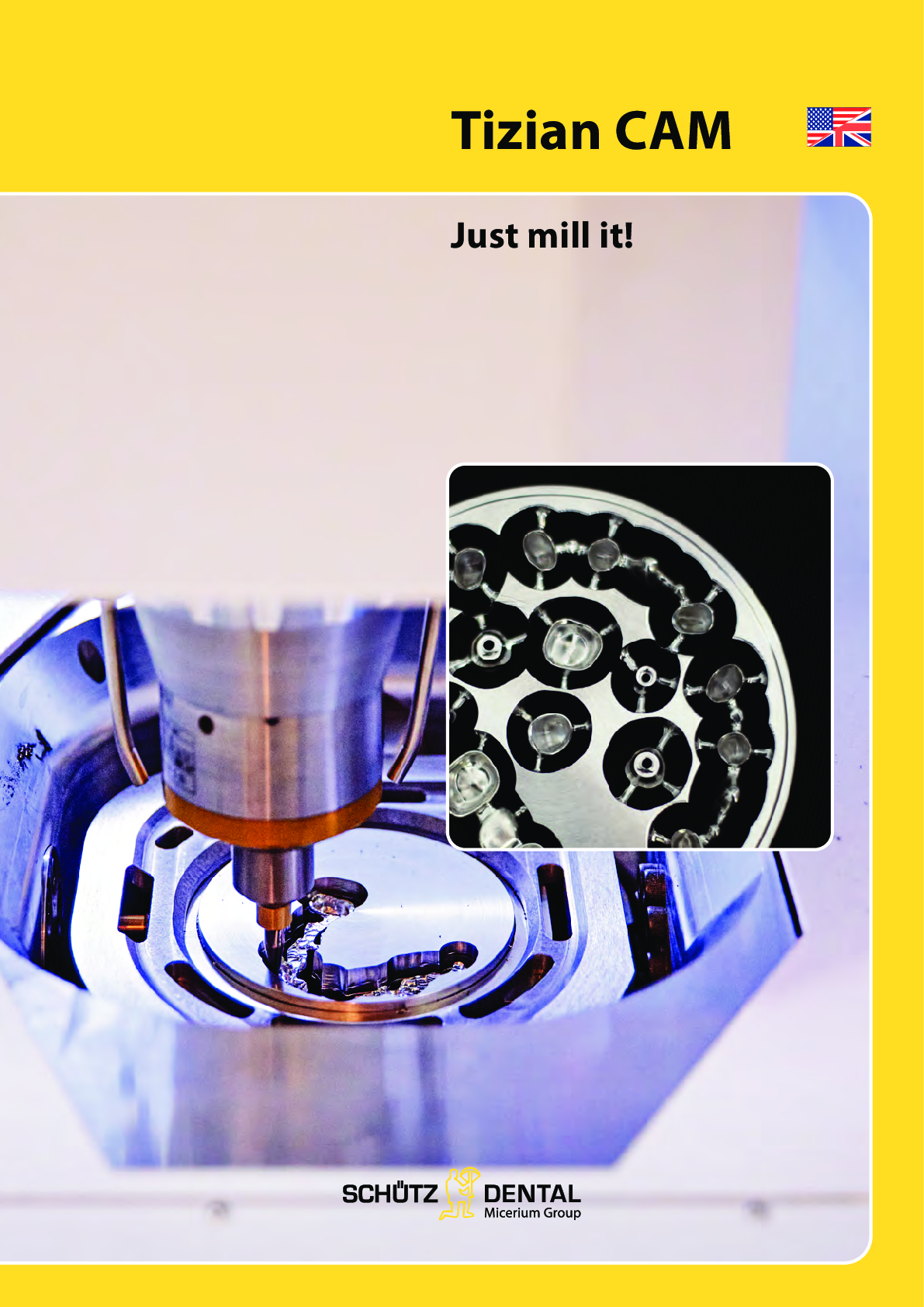

Tizian 3.5 Loader Pro+ milling machine, incl. 2.6 kw high frequency spindle, 7 stainless steel blank holders

Advantages

- Even more precise milling results

- Absolute measuring system in all axis

- an much more

Properties

- Developed for the latest requirements in CAD/CAM machining

Description

The Pro-Series for highest demands

The Pro-Series for highest demands

Designed for the modern requirements in CAD/CAM machining. Benefit from extremely high stability and low-vibration machining due to the new one-piece machine housing made from polymer concrete. What's more, the high-resolution dynamic servomotors with absolute measuring system facilitate an up to 20 % faster processing with optimal precision.

Tizian 3.5 Loader Pro+ – The professional solution:

The integrated zero-point clamping system facilitates the use of a multitude of adapter systems, such as glass ceramic adapters or different premilled systems. The machine processes restorations with a milling angle of up to 90 degrees with help of the innovative open blank holder. What's more, the Tizian 3.5 Loader Pro+ with its fully automated blank loader facilitates the multifarious processing of up to 12 blanks in unmanned operation.

Your benefits:

- Revolutionary machine base made of polymer concrete for a greater rigidity and consequently, a higher precision

- Simultaneous five-axis machining

- Absolute measuring systems in all axes

- Dry and wet machining

- Machining of all significant materials in dentistry including metals

- Working angle of the axes of up to +/- 30 degrees

- 20-fold tool changer, covered

- Machining on the face of the blank is an option (B axis in 90 degree position)

- Jäger high frequency spindle with up to 60,000 rpm

- Blank loader for up to 12 blanks (different materials)

Technical data

- Simultaneous five-axis machining

- Automated tool changer with 20 slots (optional)

- High frequency spindle, max. output power 240 V, 2.6 kW with 60,000 rpm, 6.5 bar, 100 l/min.

- Integrated wet machining function

- Integrated PC and touchscreen

- W/D/H ca. 1058 x 789 x 847 mm

- Weight ca. 250 kg

Suited for these materials:

- Titanium

- Non-precious alloys

- Zirconium dioxide

- PMMA acrylics for temporary restorations and splints

- Wax

- Composite and Zirconia reinforced composite

- PEEK materials

- Acetal acrylics

- Polycarbonate

- With additional blank holder: glass ceramics and lithium disilicate**

- Prefabricated abutments**

**Optional accessory