User Report: Alphalink Cem and PrimeBond7

Alphalink Cem and PrimeBond7

A User Report by the Dentist Maximilian Von Kleinsorgen

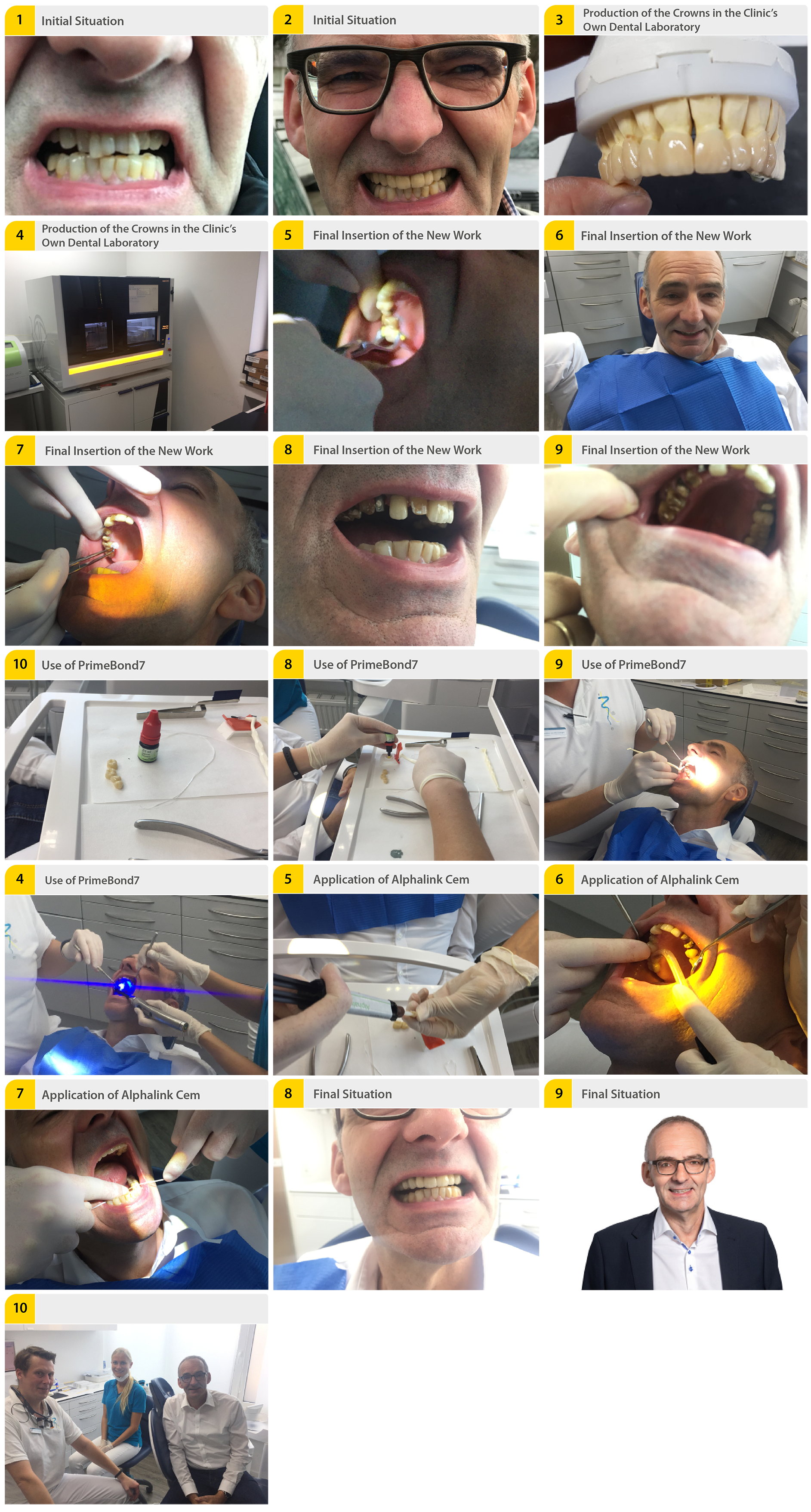

Initial Situation

At the start of the treatment, the position of the 55-year-old patient’s teeth requires visual improvement. The patient asked for a complete, aesthetically perfect restoration of the upper jaw, which will also harmonize the position of the teeth. Based on their natural appearance, high biocompatibility, and stability, the decision was taken to furnish the patient with ceramic veneered zirconium oxide crowns made from Tizian Blank 5.0 (Schütz Dental).

Following the controlled preparation of the teeth, a temporary restoration was initially applied to the patient’s upper jaw.

Production of the Crowns in the Clinic’s Own Dental Laboratory

Following the successful detailed impression and preparation of the model, the new dental prosthesis, in this case individual crowns for teeth 16–24, was manufactured in our clinic’s laboratory using our Tizian 5.2 milling machine (Schütz Dental). Even on the saw-cut model, the individually veneered crowns were already aesthetically pleasing.

Final Insertion of the New Work

On the final day of the insertion, the temporary restoration was first removed using diamond powder in order to increase the grip. The tooth stumps were thoroughly cleaned, degreased and dried with ethanol to prepare them for permanent fixing.

Use of PrimeBond7

The etching and bonding occurs using PrimeBond7 (Schütz Dental). This is a self-etching, lightcuring single-component adhesive for safely and reliably fixing adhesive luting composites or filling components to natural dental hard tissues. The adhesive can be used with either the selfetch or the selective etch technique. First, the adhesive is prepared for the adhesion process in a light-protected manner in the mixing dish.

The adhesive is applied to the entire tooth stumps in relatively dry conditions. After an exposure period of at least 20 seconds, the excess adhesive is dispersed with compressed air free of water and oil to leave only a wafer-thin layer. The process continues until the fluid film is no longer visible. Care is taken to ensure that no recontamination occurs due to moisture in the form of saliva. The adhesive is then hardened for 10 seconds using a polymerization lamp.

Application of Alphalink Cem

In line with the standard rules on preparing a restoration (cleaning, drying, wetting with the adhesive etc.), the crowns are then filled with Alphalink Cem (Schütz Dental).

Alphalink Cem is a dual-curing, fluorescent, and radiopaque luting composite used for the adhesive attachment of indirect constructions such as veneers, onlays, crowns, and bridges. Materials that can be inserted using Alphalink Cem range from glass ceramics, zirconium oxide, composite, precious and non-precious metal to titanium. This makes Alphalink Cem extremely versatile. Here, the crowns are precisely filled using the automix syringe and the material is evenly distributed across the inner walls of the restoration. The processing time varies depending on the room temperature. It takes between 3 and 4 minutes at 21 °C and approx. 2 minutes at 37 °C. The crowns are moved into position and fixed under slight pressure. Now, the curing time begins. This again depends on the room temperature, lasting between 3 and 5 minutes at 21 °C and approx. 2 to 3 minutes at 37 °C. Once the crowns have been successfully positioned, the luting composite is cured with a polymerization lamp for approx. 20 seconds. Chemical curing is complete after 6 minutes.

Once the specified curing time has elapsed, the excess luting composite is thoroughly removed using dental floss, scaler, and/or a scalpel. Particular care is taken to quickly remove the material from areas that are difficult to reach. Once the excess luting composite has been removed from the edges, the light-curing process is repeated for another 20 seconds. To prevent an oxygen inhibition layer from forming, the restoration edges can be covered in glycerin gel or an air blocker straight after the insertion. This can then be rinsed off again once curing is complete.

Final Situation

The new restoration has fully restored the harmony of the tooth position. The high-quality zirconium oxide crowns have made it possible to perfectly adapt the color and shape of the teeth to the patient.

The patient is extremely happy with the final result and enjoying his newfound quality of life. Satisfied patient, satisfied team!

Author:

Download this case study as PDF file: Please note: this report is not intended as an instruction manual. Please note the instructions for the materials and devices used. The responsibility lies with the attending dentist.