Filter

The item has been added to your inquiry list

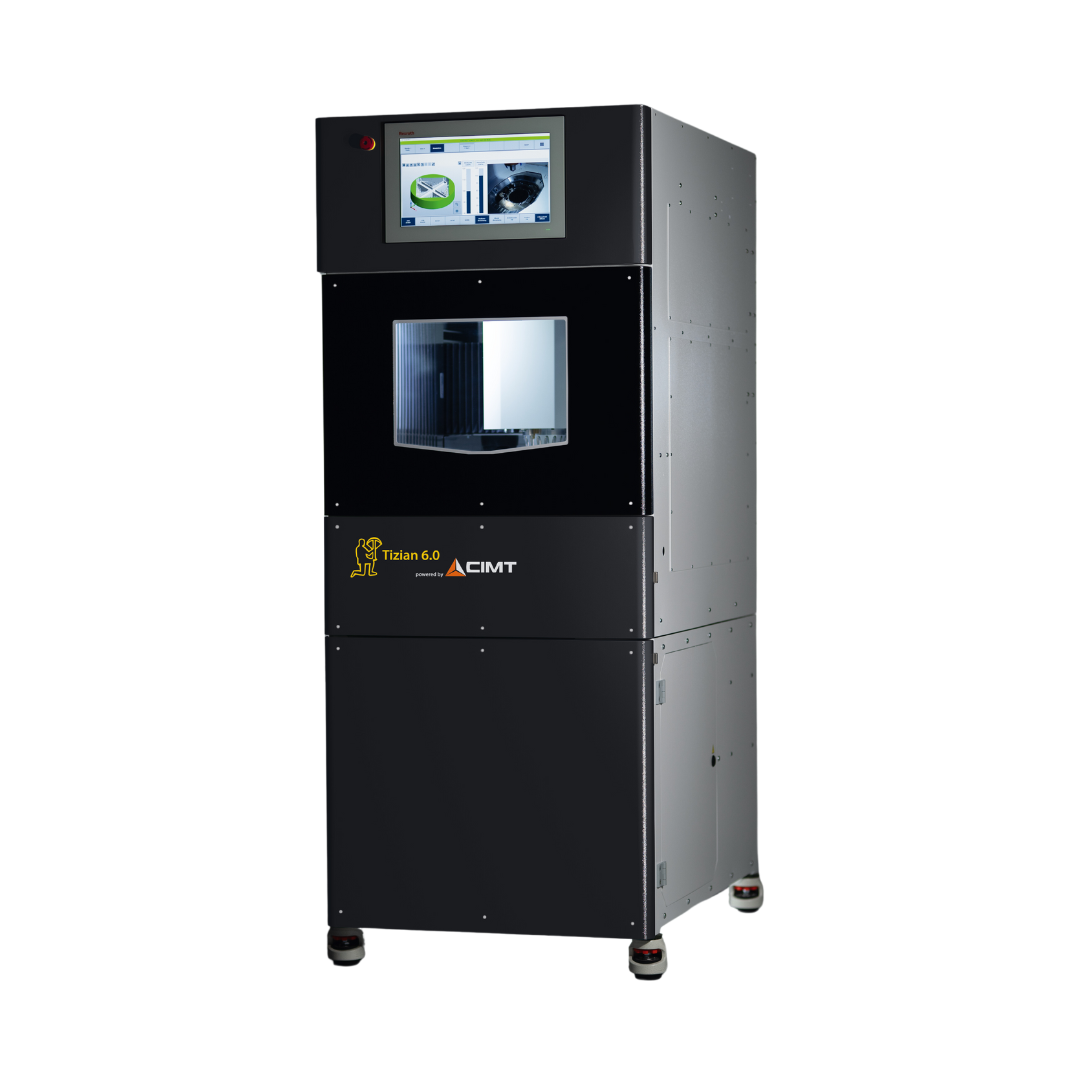

Tizian 6.0

The Tizian 6.0 milling machine combines industrial production quality with a compact design and revolutionizes dental technology with outstanding precision, efficiency and speed. Developed and manufactured in Germany, it meets the highest requirements of modern digital workflows. With innovative technologies such as 6-axis rotary milling*, a low-vibration control system and real-time calculations, the Tizian 6.0 ensures fine surfaces and maximum precision. The 15-inch multi-touch display with a specially developed, dental-specific user interface and the option of remote control make operation intuitive and convenient. The Tizian 6.0 combines speed, precision and user-friendliness for your laboratory in just one machine.

CORITEC 650i Loader, 5-axis dental miling machine

High end quality with future-oriented technology We developed the CORiTEC 650i and CORiTEC 650i Loader machine systems for the PREMIUM machine segment and for PREMIUM requirements. The systems are offered at a very attractive price and are equipped with high-quality industrial milling technologies, such as granite structure, linear drives in the linear axes, torque motors in the rotary axes, as well as digital absolute length measuring systems and powerful main spindles. The machine concept impresses with its precise, vibration-free and dynamic motion sequences in the demanding and complex metal working processes. All other relevant materials can also be milled or ground at high quality with this system (wet and/or dry machining). The CORiTEC 650i loader includes a fully integrated automatic 16-fold blank changer. This lets you to operate the machine system at full capacity around the clock without supervision, while maintaining consistent high precision. Thus, the machine system is ideally suited for large labs and milling centers, where these high quality standards and large quantities are required. Technical Highlights Solid axis structure made of polished natural granite for highly dynamic 5-axis simultaneous machining and for highly precise milling results Absolute, high-resolution measuring systems on all axes High-frequency spindle with up to 50,000 rpm and 2.3 kW with HSK 25 tool holder 32-fold fully automatic tool changer 16-fold fully automatic blank changer Integrated wet and dry machining for a multitude of materials and indications With touch screen-control Leading linear and torque motor technology Technical specifications Number of axes and machining type: 5-axis simultaneous machining Max. tilt angle for machining with 98 mm blank: A-axis +/- 30° / B-axis +/- 25° Wet processing: Integrated Maximum speed / Pmax~: 50,000 rpm / 2.3 kW Axle drives: Linear motors and torque motorsabsolute measuring systems, resolution of 0.5 ?m Tool fitting: HSK 25 Tool changer: 32-fold with chip protection cover Blank changer: with zero point clamping system / 16-fold fully automatic (loader) Weight: 930 kg Width x depth x height: 1325 x 1100 x 1940 mm Supply voltage / frequency / power: 400 V - 3 phase / 50/60 Hz / 2800 W Compressed air supply: 6-9 bar constant supply, 100 liters/minute Materials: CoCr/NEM, titanium, zirconium dioxide, aluminum oxide, PMMA, acrylics, composites, wax, glass ceramics, hybrid ceramics Compatibility: 98 mm/98.5 mm blanks, CAD/CAM blocks, nt-Trading prefabricated abutments, Medentika PreFace® abutments, Baltic Denture, Lava Frames

Tizian 3.5 Loader Pro+ milling machine, incl. 2.6 kw high frequency spindle, 7 stainless steel blank holders

The Pro-Series for highest demands Designed for the modern requirements in CAD/CAM machining. Benefit from extremely high stability and low-vibration machining due to the new one-piece machine housing made from polymer concrete. What's more, the high-resolution dynamic servomotors with absolute measuring system facilitate an up to 20 % faster processing with optimal precision. Tizian 3.5 Loader Pro+ – The professional solution: The integrated zero-point clamping system facilitates the use of a multitude of adapter systems, such as glass ceramic adapters or different premilled systems. The machine processes restorations with a milling angle of up to 90 degrees with help of the innovative open blank holder. What's more, the Tizian 3.5 Loader Pro+ with its fully automated blank loader facilitates the multifarious processing of up to 12 blanks in unmanned operation. Your benefits: Revolutionary machine base made of polymer concrete for a greater rigidity and consequently, a higher precision Simultaneous five-axis machining Absolute measuring systems in all axes Dry and wet machining Machining of all significant materials in dentistry including metals Working angle of the axes of up to +/- 30 degrees 20-fold tool changer, covered Machining on the face of the blank is an option (B axis in 90 degree position) Jäger high frequency spindle with up to 60,000 rpm Blank loader for up to 12 blanks (different materials) Technical data Simultaneous five-axis machining Automated tool changer with 20 slots (optional) High frequency spindle, max. output power 240 V, 2.6 kW with 60,000 rpm, 6.5 bar, 100 l/min. Integrated wet machining function Integrated PC and touchscreen W/D/H ca. 1058 x 789 x 847 mm Weight ca. 250 kg Suited for these materials: Titanium Non-precious alloys Zirconium dioxide PMMA acrylics for temporary restorations and splints Wax Composite and Zirconia reinforced composite PEEK materials Acetal acrylics Polycarbonate With additional blank holder: glass ceramics and lithium disilicate** Prefabricated abutments** **Optional accessory

Tizian 3.5 Loader Pro, incl. 12x blank changer, 4 blank holder, wet processing & zero point clamping system

The ideal system for milled, adhesion-fixed secondary telescopic crowns and bridges. The milling systems Tizian 3.5 Pro and Tizian 3.5 Loader Pro were developed with an innovative machine concept which is adapted to today's demands on CAD/CAM production. Benefit from extraordinary stability and vibration-free processing due to the new one-part machine frame made from polymer concrete. Additionally, the high-definition, dynamic servo motors with an absolute measuring system facilitate a processing that is 20 % faster while still offering optimal precision. Tizian 3.5 Pro - The automated all-in-one solution: Mill nearly all conventional dental CAD/CAM materials with only one milling machine. The outstanding precision of the machine even lets you process highly complex restorations such as one-part implant-supported constructions. Using the standard blank holder, the restorations are milled in five axes, with milling angles of up to 30 degrees. These advantages make the ""Tizian 3.5 Pro""-product line an excellent choice that will come up to the demands of modern dental labs and milling centers. The compact design makes the machines an alternative not only for large dental labs and milling centers, but also for small and medium-sized dental labs. Tizian 3.5 Loader Pro - the pro solution: The integrated zero-point chuck system facilitates the use of a variety of adapter systems such as adapters for glass ceramic and different premilled systems. By using the novel open blank holder, you can mill restorations at angles of up to 90 degrees. What's more, the Tizian 3.5 Loader Pro with its fully automated blank storage lets you mill up to 12 different blanks in unmanned operation. Your benefits: Blank storage for up to 12 blanks of different materials Revolutionary machine frame made from polymer concrete Simultaneous 5-axis processing Absolute measuring system in all axis Up to 20 % faster processing Wet or dry milling Processing all significant materials in dental industry, including metal processing Axial angle of up to +/- 30 degrees Milling of the front of the blank is possible (B-axis in 90 degree position) Jäger HF spindle with up to 60,000 rpm Technical data: Number of axis and type of processing: 5 axis simultaneouslyMax. milling angle when processing a 98 mm blank: A-axis +/- 30 degrees, B-axis +/- 25 degreesMax. axial angle A-axis: 360 degrees, B-axis: 115 degreesWet milling: integratedRevolution max./Pmax~: 60,000 rpm/1 kWAxial drive: AC servo motors with absolute encoder 0.15 µmTool receptacle: 6 mm shaftTool changer: 20-fold with protective cover against milling dustBlank changer: fully automated, 8-fold (optional: up to 12-fold)Weight: 250 kgWidth x depth x height: 1058 x 790 x 857 mmMains supply/frequency/performance: 100 V-240 V, 50/60 Hz, 2200 WCompressed air supply: 6-9 bar constant flow, 60 liter/minuteMaterials: CoCr/NEM, titanium, zirconium dioxide, aluminium oxide, PMMA, resins, composites, wax, glass ceramic, hybrid ceramic

Tizian 3.5 Pro+ milling system, incl. 2.6 kW high frequency spindle

The Pro-Series for highest demands Designed for the latest requirements in CAD/CAM machining. Benefit from extremely high stability and low-vibration machining thanks to the new one-piece machine housing made from polymer concrete. What's more, the high-resolution dynamic servomotors with absolute measuring system facilitate an up to 20 % faster processing with optimal precision. Tizian 3.5 Pro+ – The automated all-in-one solution: Mill all conventional CAD/CAM materials with only one machine. The extraordinary precision of the machine lets you produce even highly complex restorations such as e.g. one-piece implant-supported constructions. The standard blank holder is used to produce restorations with milling angles of up to 30 degrees. This makes the ""Tizian 3.5 Pro""-series an excellent choice for the high demands of dental laboratories and milling centers. It has been some time since Tizian milling machines have only attracted large dental labs and milling centers – with the latest, very compact design of the machines, they have also become a very popular option for small and medium-sized labs. Your benefits: Revolutionary machine base made of polymer concrete for a greater rigidity and consequently, a higher precision Simultaneous five-axis machining Absolute measuring systems in all axes Dry and wet machining Machining of all significant materials in dentistry, including metals Working angle of the axes of up to +/- 30 degrees 20-fold tool changer, covered Machining on the face of the blank is an option (B-axis in 90 degree position) Jäger high frequency spindle with up to 60,000 rpm Technical data Simultaneous five-axis machining Automated tool changer with 20 slots (optional) High frequency spindle, max. output power 240 V, 2.6 kW with 60,000 rpm, 6.5 bar, 100 l/min. Integrated wet machining function Integrated PC and touchscreen W/D/H ca. 758 x 790 x 857 mm Weight ca. 205 kg Suited for these materials: Titanium Non-precious alloys Zirconium dioxide PMMA acrylics for temporary restorations and splints Wax Composite and Zirconia reinforced composite PEEK materials Acetal acrylics Polycarbonate With additional blank holder: glass ceramics and lithium disilicate* Vorgefertigte abutments** **Optional accessory

Tizian 3.5 Pro milling machine, incl. wet processing, polymer concrete, zero point clamping system & 2 blank holder

The ideal system for milled, adhesion-fixed secondary telescopic crowns and bridges. The milling systems Tizian 3.5 Pro and Tizian 3.5 Loader Pro were developed with an innovative machine concept which is adapted to today's demands on CAD/CAM production. Benefit from extraordinary stability and vibration-free processing due to the new one-part machine frame made from polymer concrete. Additionally, the high-definition, dynamic servo motors with an absolute measuring system facilitate a processing that is 20 % faster while still offering optimal precision. Tizian 3.5 Pro - The automated all-in-one solution: Mill nearly all conventional dental CAD/CAM materials with only one milling machine. The outstanding precision of the machine even lets you process highly complex restorations such as one-part implant-supported constructions. Using the standard blank holder, the restorations are milled in five axes, with milling angles of up to 30 degrees. These advantages make the ""Tizian 3.5 Pro""-product line an excellent choice that will come up to the demands of modern dental labs and milling centers. The compact design makes the machines an alternative not only for large dental labs and milling centers, but also for small and medium-sized dental labs. Your benefits: Revolutionary machine frame made from polymer concrete Simultaneous 5-axis processing Absolute measuring system in all axis Up to 20 % faster processing Wet or dry milling Processing all significant materials in dental industry, including metal processing Axial angle of up to +/- 30 degrees Milling of the front of the blank is possible (B-axis in 90 degree position) Jäger HF spindle with up to 60,000 rpm Technical data: Number of axis and type of processing: 5 axis simultaneously Max. milling angle when processing a 98 mm blank: A-axis +/- 30 degrees, B-axis +/- 25 degrees Max. axial angle A-axis: 360 degrees, B-axis: 115 degrees Wet milling: integrated Revolution max./Pmax~: 60,000 rpm/1 kW Axial drive: AC servo motors with absolute encoder 0.15 µm Tool receptacle: 6 mm shaft Tool changer: 20-fold with protective cover against milling dust Blank changer: manual with zero point chuck system (incl. 3 blank holders) Weight: 205 kg Width x depth x height: 758 x 790 x 857 mm Mains supply/frequency/performance: 100 V-240 V, 50/60 Hz, 2200 W Compressed air supply: 6-9 bar constant flow, 60 liter/minute Materials: CoCr/NEM, titanium, zirconium dioxide, aluminium oxide, PMMA, resins, composites, wax, glass ceramic, hybrid ceramic

Tizian JMA Optic System by zebris

Welcome to the world of functional digital dentistry - the new dimension of the function-oriented digital workflow: The JMA Optic - precise, safe, fast and economic! The JMA Optic System is based upon the latest optical sensor technology and thus, it is the latest development in the field of functional dentistry. Your benefits: Safe prosthetics Forensic backstop Documentation Additional profits Happy patients Digital image for your dental clinic Decisive advantage towards your competition Real Movement: Transfer real patient data or the settings of virtual articulators via a standardized XML-export to external CAD systems (Tizian CAD/CAM System). With this extraordinary feature, the system becomes an integral component of Schütz Dental's Digital Workflow for the production of functional dental prostheses. A patented bite tray creates a precise relation between the movement data of the measuring system and the tooth surfaces scanned by the model scanner (Tizian Smart-Scan Plus) or the Intraoral Scanner (i500). This tray is also a part of the new zebris transfer appliance and facilitates a smooth transfer of the position of the maxilla in relation to the skull to a mechanical articulator. Thus, the use of a mechanical facebow becomes unnecessary. Precise: The analyser consists of a manageable stand-alone headbow with a mandible sensor. Aside from scanning the condyle movement, the user can also record all six mobility levels of the mandible with high precision. Fast: The user has the option to operate the system via a USB interface or wireless via WiFi. The headbow is attached in just a few steps with the nasion support, a head band and the support parts fixed to spring-mounted sidebars. Enter a defined reference plane with the supplied T-stylus right on the head. Safe: The table-top mount contained in the basic system facilitates a safe storage of the measuring components, whereas the battery powered headbow can be charged simultaneously via the integrated inductive charger. The extremely small and light mandible sensor is fixed with the help of a magnet to the paraocclusal and occlusal attachments, and then it is connected to the lower-jaw teeth. The analysis software WINJAW+ with its modular setup can be handled intuitively and contains: a data base, the basic module for the determination of the setting parameters of mechanical and virtual articulators as well as the export function for real movements. Optional are additional modules for functional analysis, for position analysis of the condyles and for the determination of neuro-muscular jaw relations and the Plane Finder Module. The system contains: Electronic headbow Mandible sensor T-stylus Analysis software WINJAW+ with basic module articulator and data export Table mount/inductive charger Foot switch/manual switch (wireless) Attachments Instructions Transport case Optional: Various additional software modules The system is operated with a conventional computer equipped with the system software Windows 10. Basic color: white RAL 9003

iVAC expert suction unit,

iVAC expert - the extraction system for CORiTEC 650i and 650i Loader milling systems. Your benefits: High extraction capacity with 1000 m³/h and 100 liters filter capacity and HEPA-filter. Brush-free turbine guarantees a long service life. Ideal for CORiTEC 650i and 650i Loader. Technical data: Volume flow rate: 1000 m³/h Capacity: 2200 W Filter system: HEPA filter Filter capacity: 100 liters Width x depth x height 600 x 770 x1220 mm Mains voltage: 115 V/230 V

Zero point clamping system, for Tizian 3.5

Zero-point clamping system for mounting material blocks. Facilitates the use of various adapters and clamping systems. Furthmore, it makes a quick change of blanks (incl. the blank holder) possible.

Tizian 3.5 Loader Pro + unit desk, for Tizian 3.5 Pro + milling machine

This pleasantly designed cabinet was developed for the special requirements of Tizian Cut 5.2 plus and offers enough room for placing the machine. The robust wheels of the cabinet guarantee optimal stability and facilitate moving the machine. The cabinet contains drawers and cable ducts, and it accommodates the extraction system. Dimensions: 1060 x 930 x 790 mm (w x h x d)

Tizian 3.5 Loader unit desk, for Tizian 3.5 Loader milling machine

This pleasantly designed cabinet was developed for the special requirements of Tizian Cut 5.2 and offers enough room for placing the machine. The robust wheels of the cabinet guarantee optimal stability and facilitate moving the machine. The cabinet contains drawers and cable ducts, and it accommodates the extraction system. Dimensions: 770 x 930 x 790 mm (w x h x d)

Medentika PreFace abutment holder, for Tizian 3.5 and 3.5 Loader milling machines

MEDENTIKA® Preface® Abutment Holder for an effective production. Combine the MEDENTIKA® Preface® Abutment Holder with our Preface® Abutments and the Tizian Cut 5.2 or Tizian Cut 5.2 Plus milling machines.

zebris module EPA, for zebris JMT Function pro

The electronic position analysis of the condyles (EPA) allows you to compare different occlusion positions and it can thus lead you to detect possible pain vectors in the jaw joint. You will see how the position of the condyles in the joint changes. Additional measuring modules (optional) determine the palatinal posterior tooth correction as well as the analysis of mastication movements.

zebris module functional analysis, for zebris JMT Function pro

Additional module for recording all levels of freedom of movement in the lower jaw.

Astron Clearsplint CAD/CAM Pro Super Economy Kit, 960g powder/ 720g monomer

Clearsplint® CAD/CAM pro – The ideal solution for indications such as relieving the joint in case of bruxism, protecting full metal crowns and implant-supported restorations, readjusting the bite etc. Benefits: Extremely break-proof, offers an optimal protection for the natural teeth Thermo-active flexibility for excellent, comfortable and stress-free wear Hypoallergenic, MMA-free (residual monomer MMA = 0 %) Self-adjusting with memory effect Long-lasting transparency – no yellow discoloration, as the material is free of amines Present the advantages of excellent wearing comfort and flexibility of the splint to your customers The splint is an optical highlight, because it remains complete transparet.

Blank holder for Tizian 3.5 Pro Plus machine, (not suitable for Tizian 3.5 Loader milling machine)

The zero-point clamping system incl. blank holder facilitates an easy exchange of blank and blank holder at the touch of a button.

Zebris digital transfer table, for Artex crtikulator with Splitex Split system

For your zebris JMAnalyser+ system or your Tizian JMA Optic system by zebris Facilitates the transfer of the jaw position to the Artex articulator with the Splitex® Split System. Includes 3 pc. bite fork, type SD with screw thread, bite fork adapter, set of positioning screws, 3 pc. fixing nuts, 5 pc. positioning foil and brief instructions.

zebris digital transfer table, for JMAnalyser+

The digital transfer table for the zebris JMAnalyser+ system facilitates the transfer of a jaw position to the Artex Articulator with help of a bite fork type SD. Scope of delivery: 3 bite forks type SD with screw thread Bite fork adapter System case 1 set of positioning screws (3 pcs. of each type) 5 positioning foils

Blank holder for Tizian 3.5 Loader milling machine,

The zero-point clamping system incl. blank holder facilitates an easy exchange of blank and blank holder at the touch of a button.

zebris module for database configuration, for zebris JMT Function pro

Save your very precious time with the zebris database configuration module. There are more important things to do than having to concern yourself with bureaucracy and data base maintenance.Until now, a fixed export path is specified e.g. for the storage of patient data on the server of your practice network. This additional module lets you freely choose the data base export path. What's more: The patient data is now not only saved on the local computer, but this module creates an automatic daily data backup on the server of your practice. Of course, manual backups are still possible.Your benefits: Free choice of the export path Daily automatic backup of your patient data Enormous time-savings, lightens your workload

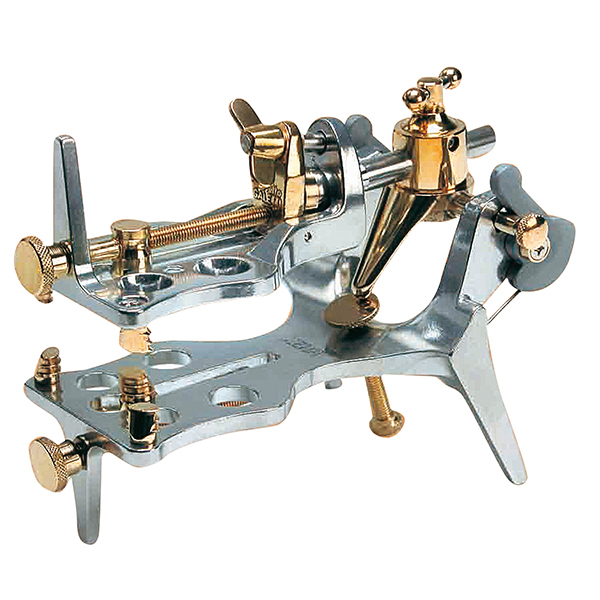

Articulator Galetti,

Articulator for the individual adjustment of your plaster models. Benefits: Immediate fitting for checking the impression material: You can check you impression results, while the patient is still there. Optimized kinematic reduced subsidence error when compared with conventional articulators, also without face bow transfer. Ideal forfunctional diagnostic purposes/fast occlusion analysis. Fast preparation of registration aids: Whether it’s a para-occlusal tray, impression material templates for incisal pins, ballistic registrations or conventional centering plates. Fast fitting perfectly supports all technical preparations for an impression. Manufacture of perfectly fitting silicone keys for condyle position analysis (zebris EPA) in the correct relation to the jaw. Optimized work flow when making and checking splints. Immediate fitting after a new impression means you can grind a splint straight away in the articulator, in the same sitting.

zebris C-bow, for Tizian JMA Optic System by zebris

The new C-bow for your Tizian JMA Optic System by zebris replaces the former T-pointer. Enter a defined reference plane of your patient's head with the C-bow. With its quick and easy handling, this accessory will offer you an your patient an even higher level of comfort during the measuring procedure.

priti®MPguide ZrO2 High Translucent,

The priti®MPguide High Translucent shows the positioning in the blank. This product lets you select the precise shade using pritidenta® zirconium. The priti®MPguide High Translucent: provides the full shade selection from all ZrO2 multicolor technology colors can be mapped to both shade systems, VITA classical® and VITA System 3D-Master®

Scan attachment/ tip (4 pcs.), for intraoral-scanner i700 wireless

Variante:

Scanaufsatz/Tip (4 Stück)

4 Scan-Aufsätze für Ihren Medit i700w/i700/i600 Intraoral-Scanner. Zur einfachen Anwendung im posterioren Bereich bei Patienten mit kleiner Mundhöhle Größe der Spitze: 14,8 x 19,0 mm (B x H) Bis zu 150x autoklavierbar

zebris double electrode FIAB Typ F3010, Noraxon type 272

For attaching the zebris EMG electrodes to the indicated position on the patient’s body.

Scan attachment/ tip (4 pcs.), for intra oral scanner i500

The small tip of the Intraoral Scanner i500 facilitates its handling and, at the same time, increases the precision of the result. What's more, it makes the treatment more comfortable for your patients. Tip size: 19 x 52 mm (w x h)

Measuring probe insert type B (1mm),

Measuring probe for scanning. Records hundreds of points on the surface per second. Thus, it can measure shapes, sizes and positions.

Measuring probe insert type B (3 mm),

Measuring probe for scanning. Records hundreds of points on the surface per second. Thus, it can measure shapes, sizes and positions.

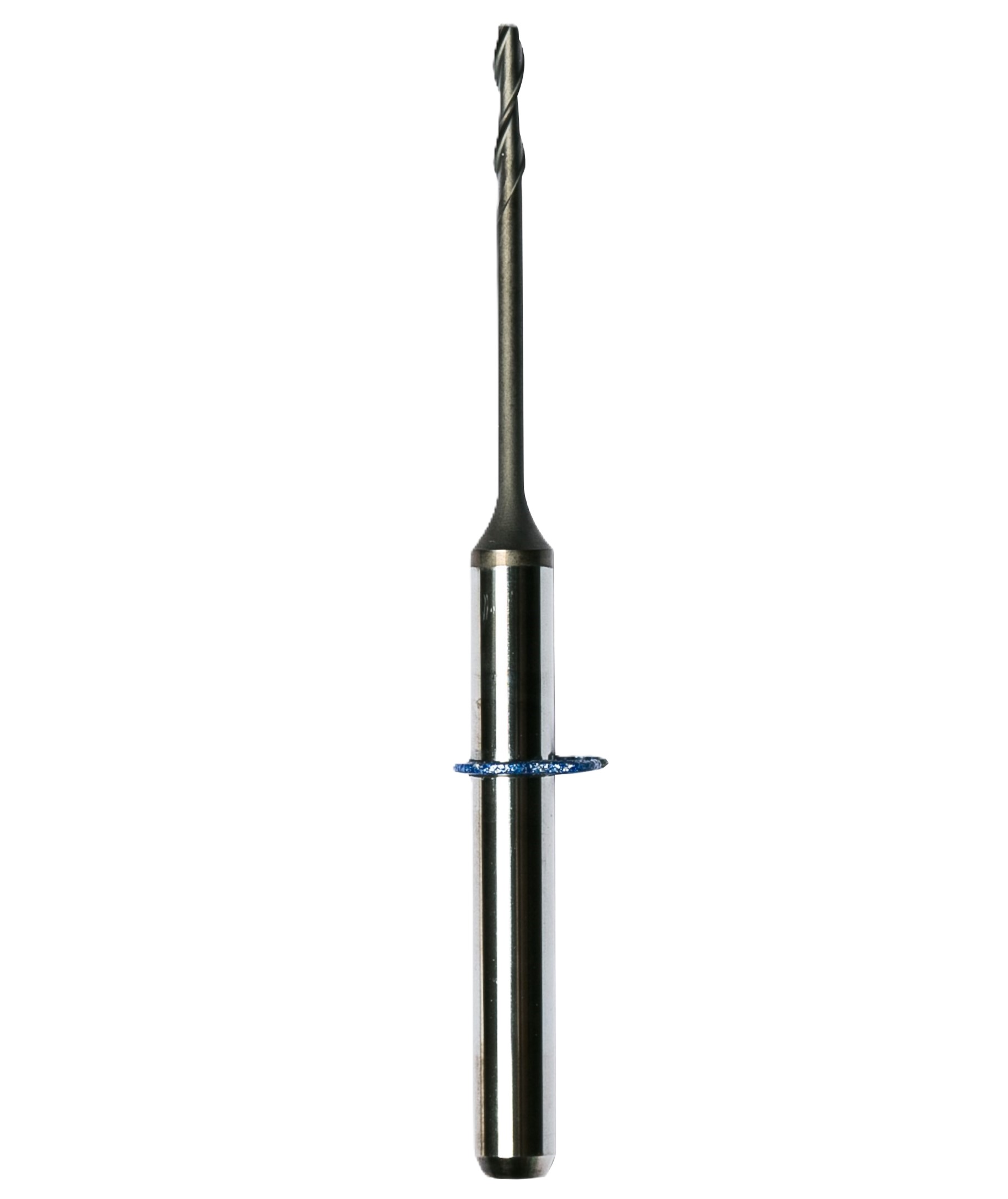

Radius cutter, 0,6 mm, diamond coating, zirconium dioxide, for Tizian Cut 5 Smart

Radius cutter, double-edged, edge Ø 0.6 mm, shaft Ø 3 mm, total length 40 mm Processing type: removal of material residue Blank material: zirconium dioxide Coating type: diamond Ring color: dark blue For milling machine: Tizian Cut 5 smart, Tizian Cut 5 smart plus Up to seven times greater tool life "

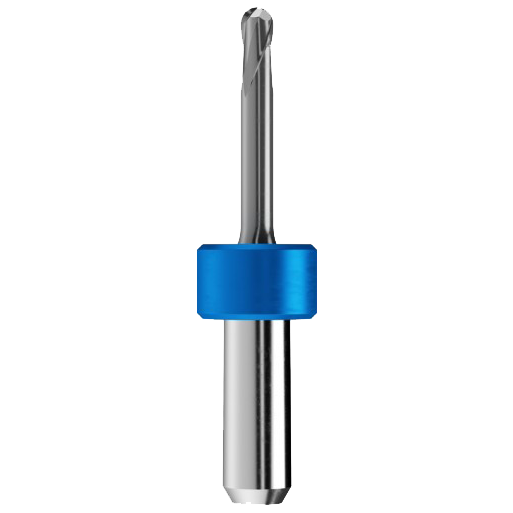

Radius cutter, 1,0 mm, diamond coating, zirconium dioxide, for Tizian Cut 5 smart

Radius cutter, double-edged, edge Ø 1 mm, shaft Ø 3 mm, total length 40 mm Processing type: fine finishing Blank material: zirconium dioxide Coating type: diamond Ring color: dark blue For milling machine: Tizian Cut 5 smart, Tizian Cut 5 smart plus Up to seven times greater tool life "

Radius cutter, 2,0 mm, diamond coating, zirconium dioxide, for Tizian Cut 5 smart

Radius cutter, triple-edged, edge Ø 2 mm, shaft Ø 3 mm, total length 40 mm Processing type: pilot milling Blank material: zirconium dioxide Coating type: diamond Ring color: dark blue For milling machine: Tizian Cut 5 smart, Tizian Cut 5 smart plus Up to seven times greater tool life "

T13/T40/T50Tizian Cut 5/3.5 Zirconia Drill diamond 2.5mm, 6 mm shaft

Diamond radius cutter, double-edged, edge Ø 2.5 mm, shaft Ø 6 mm, total length 53 mm Processing type: roughing Blank material: zirconium, nano-composite Type: coated Coding color: gold For the milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5 option metal milling (6 mm shaft), CORiTEC 550i, CORiTEC 650i

T14/T41/T51 Tizian Cut 5/3.5 Zirconia Drill diamond 1mm, 6 mm shaft

Diamond radius cutter, double-edged, edge Ø 1 mm, shaft Ø 6 mm, total length 53 mm, max. blank height: 25 mm Processing type: fine finishing Blank material: zirconium, nano-composite Type: coated Coding color: gold For the milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5 option metal milling (6 mm shaft), CORiTEC 550i, CORiTEC 650i

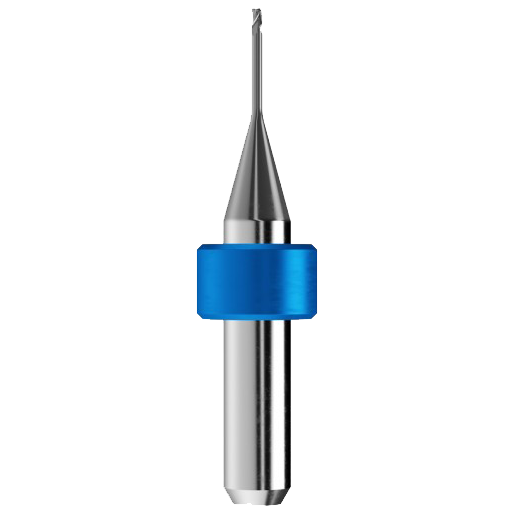

Double-toothed drill, 1,20 mm, diamond coating, zirconium dioxide, for Tizian Cut 5 smart

Flat cutter, double-edged, edge Ø 1.2 mm, shaft Ø 3 mm, total length 40 mm. The flat mill has an angle of 90°. Processing type: inside of screw seatings, implants, bars Blank material: zirconium dioxide Coating type: diamond Ring color: dark blue For milling machine: Tizian Cut 5 smart, Tizian Cut 5 smart plus Up to seven times greater tool life "

T33/T43/T53 Tizian Cut 5/3.5 Zirconium/PMMA/Wax fissures-mill 0,3mm, 6mm shaft

Radius cutter double-edged, edge Ø 0.3 mm, shaft Ø 6 mm, total length 45 mm, max. blank height: 25 mm Processing type: removal of material residue Blank material: zirconium dioxide, PMMA, wax Coating type: coated Ring color: gold For milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5 option metal milling (6 mm shaft), CORiTEC 550i, CORiTEC 650i

T14/T41/T51Tizian Cut 5/Tizian 1.5/ 2.5/ 3.5 zirconium drill diamond 1 mm, 3 mm shaft

Diamond radius cutter, double-edged, edge Ø 1 mm, shaft Ø 3 mm, total length 48 mm. Max. blank height = 25 mm. Processing type: fine finishing Blank material: zirconium Type: diamond polished Coding color: gold For the milling machines: Tizian 1.5, Tizian 2.5, Tizian Cut 5 without optional metal milling (3 mm shaft)

T13 Tizian Cut 5/Tizian 1.5/ 2.5/ 3.5 zirconium drill diamond 2.5 mm, 3 mm shaft

Diamond radius cutter, double-edged, edge Ø 2.5 mm, shaft Ø 3 mm, total length 48 mm. Max. blank height = 25 mm. Processing type: roughing Blank material: zirconium Type: diamond polished Coding color: gold For the milling machines: Tizian Cut 5 without optional metal milling (3 mm shaft)

Tizian 3.5 3,0 mm premium radius cutter long for CoCr/Ti, T26, for 6 mm chuck

T26 radius cutter, two-edged, edge Ø 3.0 mm, shaft Ø 6 mm, max. blank height = 16 mm respectively 25 mm. For a blank height of 16 mm or higher, we recommend the use of T26 (art.-no. 523985) Finishing type: rough pre-machining Blank material: CoCr, titanium Coating type: coated Ring color gold For milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5.2 Pro, Tizian Cut 5.2 Pro plus, CORiTEC 550i, CORiTEC 650i

Tizian 3.5 3,0 mm premium radius cutter for CoCr/Ti, T1/T6, for 6 mm chuck

T1/T6 radius cutter, two-edged, edge Ø 3.0 mm, shaft Ø 6 mm, max. blank height = 16 mm. For a blank height of 16 mm or higher, we recommend the use of T26 (art.-no. 523985) Finishing type: rough pre-machining Blank material: CoCr, titanium Coating type: coated Ring color gold For milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5.2 Pro, Tizian Cut 5.2 Pro plus, CORiTEC 550i, CORiTEC 650i

Tizian 3.5 0,6 mm premium radius cutter for CoCr/Ti, T20, for 6 mm chuck

T20 radius mill, double-edged, edge Ø 0.6 mm, shaft Ø 6 mm, max. blank height = 25 mm. Robust tool for milling in the occlusal area. Finishing type: fine finishing Blank material: CoCr, titanium Coating type: coated Ring color gold For milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5.2 Pro, Tizian Cut 5.2 Pro plus, CORiTEC 550i, CORiTEC 650i

Tizian 3.5 2,0 mm premium radius cutter for CoCr/Ti, T2/T7, for 6 mm chuck

T2/T7, mill for pre-finishing, double-edged, edge Ø 2.0 mm, shaft Ø 6 mm, max. blank height = 25 mm. Finishing type: pre-finishing Blank material: CoCr, titanium Coating type: coated Ring color gold For milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5.2 Pro, Tizian Cut 5.2 Pro plus, CORiTEC 550i, CORiTEC 650i

Tizian 3.5 1.5mm Premium torus mill for CoCr/Ti, T45, for 6mm chuck

T45 - Torus cutter for bars and abutments, triple-edged, cutting edge Ø 1.5 mm, shaft Ø 6 mm, total length 45 mm. Processing type: pre-finishing Blank material: CoCr, titanium Coating type: coated For milling machines: Tizian Cut 5.2 Pro, Tizian Cut 5.2 Pro Plus, Tizian Cut 5.2, Tizian Cut 5.2 plus, CORiTEC 550i, CORiTEC 650i

T46 Tizian 3.5 1.0 mm premium torus drill for CoCr/Ti, T46, for 6 mm chuck

T46 - Torus drill, triple-edged, edge Ø 1.0 mm, shaft Ø 6 mm, total length 45 mm. Blank material: CoCr, titanium Coating type: coated For milling machines: Tizian Cut 5.2 Pro, Tizian Cut 5.2 Pro Plus, Tizian Cut 5.2, Tizian Cut 5.2 plus, CORiTEC 550i, CORiTEC 650i

T32 Tizian Cut 5/3.5 radius cutter for zirconia/PMMA/Wax, 0.6 mm, 6 mm shaft

T32 double-edged radius cutter, long, edge Ø 0.6 mm, shaft Ø 6 mm, max. blank height = 25 mm. Processing type: fine finishing Blank material: zirconium dioxide, PMMA, wax Coating type: uncoated Ring color: gold For milling machines: Tizian Cut 5, Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5.2 Pro, Tizian Cut 5.2 Pro plus, CORiTEC 550i, CORiTEC 650i

Tizian 3.5 1,5 mm premium flat drill for CoCr/Ti, T5/T10, for 6 mm chuck

T5/T10 shaft mill, double-edged, edge Ø 1.5 mm, shaft Ø 6 mm, max. blank heights = 25 mm. Finishing type: drilling screw threads, production of screw bearings Blank material: CoCr, titanium Coating type: coated Ring color gold For milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5.2 Pro, Tizian Cut 5.2 Pro plus, CORiTEC 550i, CORiTEC 650i

T15/T42T52 Tizian Cut 5/3.5 Zirconia / PMMA drill 0.6mm, 6 mm shaft

Radius cutter, double-edged, edge Ø 0.6 mm, shaft Ø 6 mm, total length 53 mm, max. blank height: 25 mm Processing type: removal of residual material Blank material: zirconium, PMMA, wax, Lava Ultimate from 3M Espe, Tizian Zirconia Reinforced Composite Type: uncoated Coding color: gold For the milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5 option metal milling (6 mm shaft), CORiTEC 550i, CORiTEC 650i

T5/T10 4-Tooth mill 1.5 mm for Zirconium/PMMA/Wax/non-precious alloys/Titanium, for Tizian Cut 5/5.2 with 6 mm shaft

Flat-headed shaft mill short, four-edged, edge Ø 1.5 mm, shaft Ø 6 mm, total length 45 mm. Max. blank height = short up to 15 mm, long up to 20 mm. Finishing type: drilling screw threads, working on bars Blank material: CoCr, titanium, zirconium, PMMA, wax Coating type: coated Ring color: gold For milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5 with metal option (6 mm shaft), CORiTEC 550i, CORiTEC 650i "

T3/T8 Tizian Cut 5/3.5 ball-headed metal drill 1,5, CoCr/Ti balltop

Ball-end mill, double-edged, edge Ø 1.5 mm, shaft Ø 6 mm, total length 48 mm Processing type: drilling a screw channel Blank material: CoCr, titanium Type: coated Coding color: gold For the milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5 option metal milling (6 mm shaft), CORiTEC 550i, CORiTEC 650i