Sebond Grip, 3 g,

Advantages

- Good fluidity

- Thin bonding coat

- Considerably faster polymerisation

- High bond strength

Properties

- For acrylic veneers

Description

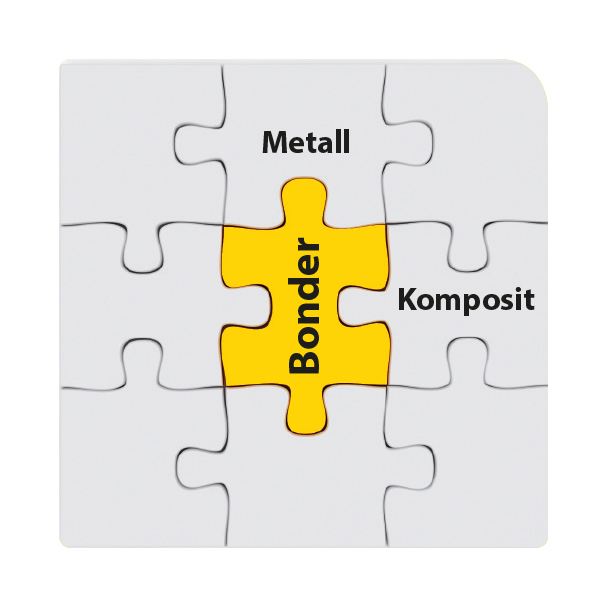

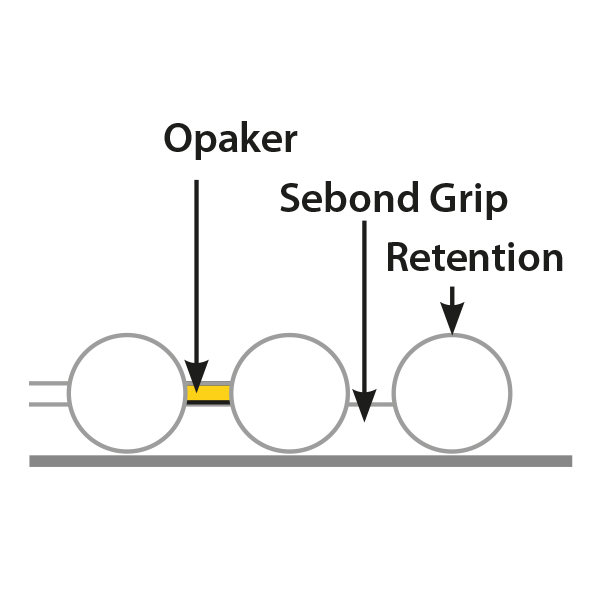

A light-curing universal opaque, which makes your composite veneers even more secure. Your additional mechanical retention.

Product number:

644092

Questions about the product? We are glad to be here for you!

Product information "Sebond Grip, 3 g,"

The additional mechanical retention for even greater security

Indications:

- For acrylic veneers

Benefits:

- Sebond Grip is simply applied between the metal bonder and the paste opaque.

- Good fluidity - thin bonding coat to the primer on metal.

- Low pigmentation - considerably faster polymerisation.

- High bond strength, and very good chemical bonding to any paste opaque.

- Good bonding, even with systems without a metal bonder

- Chewing pressure and shear force stand no chance with Sebond Grip.

Contents: 3 g syringe Sebond Grip

Brochures and further information on this product