Tizian 3.5 Pro+ milling system, incl. 2.6 kW high frequency spindle

Advantages

- Even more precise milling results

- Absolute measuring systems in all axis

- And much more

Properties

- Developed to satisfy the latest requirements in CAD/CAM machining

Description

The Pro-Series for highest demands

The Pro-Series for highest demands

Designed for the latest requirements in CAD/CAM machining. Benefit from extremely high stability and low-vibration machining thanks to the new one-piece machine housing made from polymer concrete. What's more, the high-resolution dynamic servomotors with absolute measuring system facilitate an up to 20 % faster processing with optimal precision.

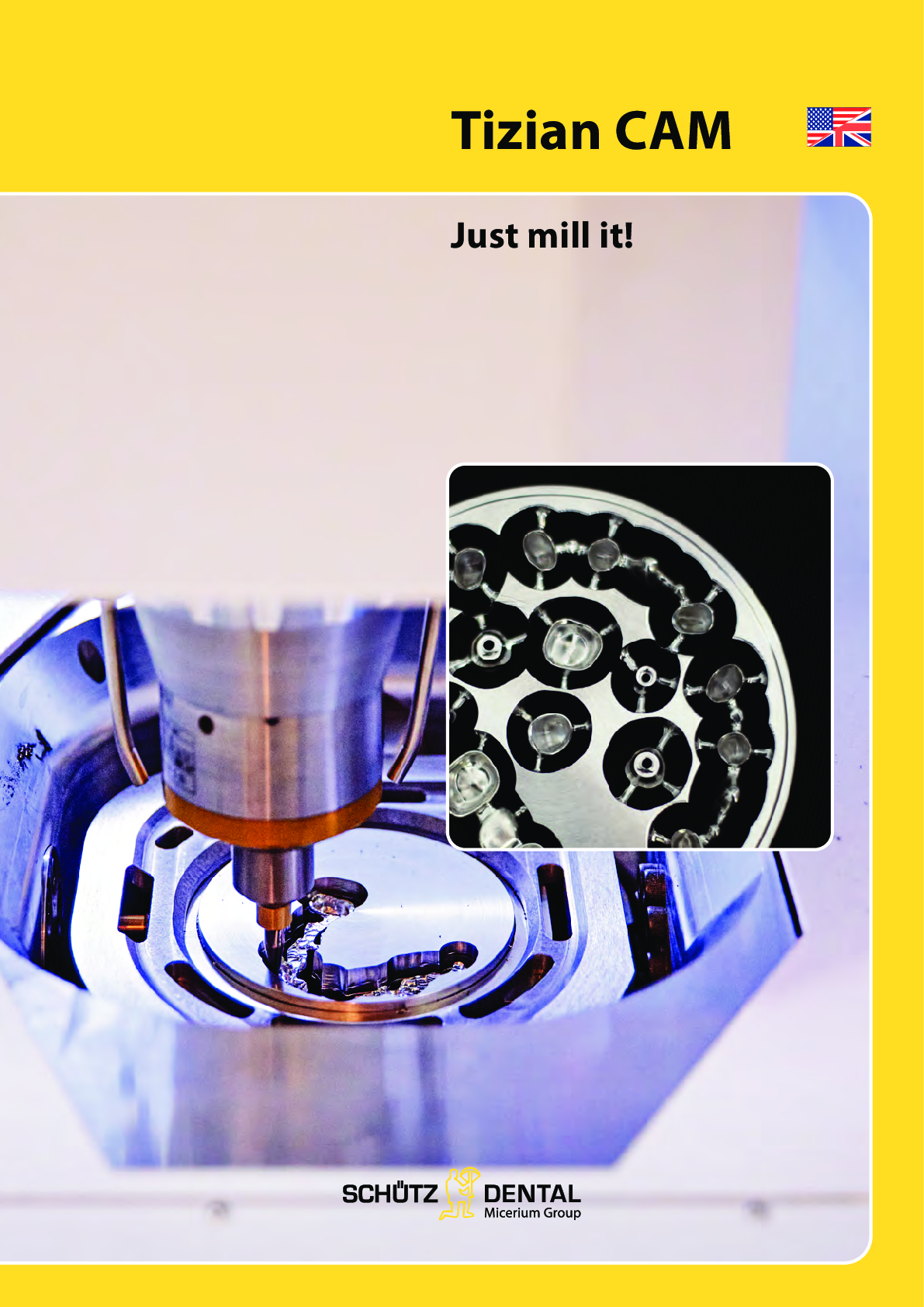

Tizian 3.5 Pro+ – The automated all-in-one solution:

Mill all conventional CAD/CAM materials with only one machine. The extraordinary precision of the machine lets you produce even highly complex restorations such as e.g. one-piece implant-supported constructions. The standard blank holder is used to produce restorations with milling angles of up to 30 degrees. This makes the ""Tizian 3.5 Pro""-series an excellent choice for the high demands of dental laboratories and milling centers. It has been some time since Tizian milling machines have only attracted large dental labs and milling centers – with the latest, very compact design of the machines, they have also become a very popular option for small and medium-sized labs.

Your benefits:

- Revolutionary machine base made of polymer concrete for a greater rigidity and consequently, a higher precision

- Simultaneous five-axis machining

- Absolute measuring systems in all axes

- Dry and wet machining

- Machining of all significant materials in dentistry, including metals

- Working angle of the axes of up to +/- 30 degrees

- 20-fold tool changer, covered

- Machining on the face of the blank is an option (B-axis in 90 degree position)

- Jäger high frequency spindle with up to 60,000 rpm

Technical data

- Simultaneous five-axis machining

- Automated tool changer with 20 slots (optional)

- High frequency spindle, max. output power 240 V, 2.6 kW with 60,000 rpm, 6.5 bar, 100 l/min.

- Integrated wet machining function

- Integrated PC and touchscreen

- W/D/H ca. 758 x 790 x 857 mm

- Weight ca. 205 kg

Suited for these materials:

- Titanium

- Non-precious alloys

- Zirconium dioxide

- PMMA acrylics for temporary restorations and splints

- Wax

- Composite and Zirconia reinforced composite

- PEEK materials

- Acetal acrylics

- Polycarbonate

- With additional blank holder: glass ceramics and lithium disilicate*

- Vorgefertigte abutments**

**Optional accessory